Check out our new interactive tool to determine what analytical tools may be applicable to your needs.

Check out our new interactive tool to determine what analytical tools may be applicable to your needs.

Analytical Answers, Inc. 4 Arrow Drive :: Woburn, MA 01801 USA +1-781-938-0300 answers@analyticalanswersinc.com

+1-781-938-0300 phone +1-781-935-5087 fax answers@analyticalanswersinc.com

© 2019-2020 , Analytical Answers, Inc

Rockwell and Knoop microhardness testing are two methods of testing and documenting the hardness of materials, primarily metals. Rockwell is the “standard” test method and requires a ‘bulk’ sample or very thick layers (if tested in cross section). For thinner material layers and somewhat softer materials, Knoop testing uses a finer-point probe.

is a method of testing the hardness of polymer materials. Manufacturing specifications for many structural plastics and other polymers require a specific Durometer (D).

Mechanical polishing of samples in cross section is often needed to inspect or measure structures in semiconductor devices, or layers in plated or multi-layer materials. Samples are typically mounted in an epoxy and polished through a graded series of abrasive materials until a mirror-smooth surface is obtained. With our technology, we are able to achieve a precision lapped cross section through two (2) 25µm structures spaced approximately 25 mm apart.

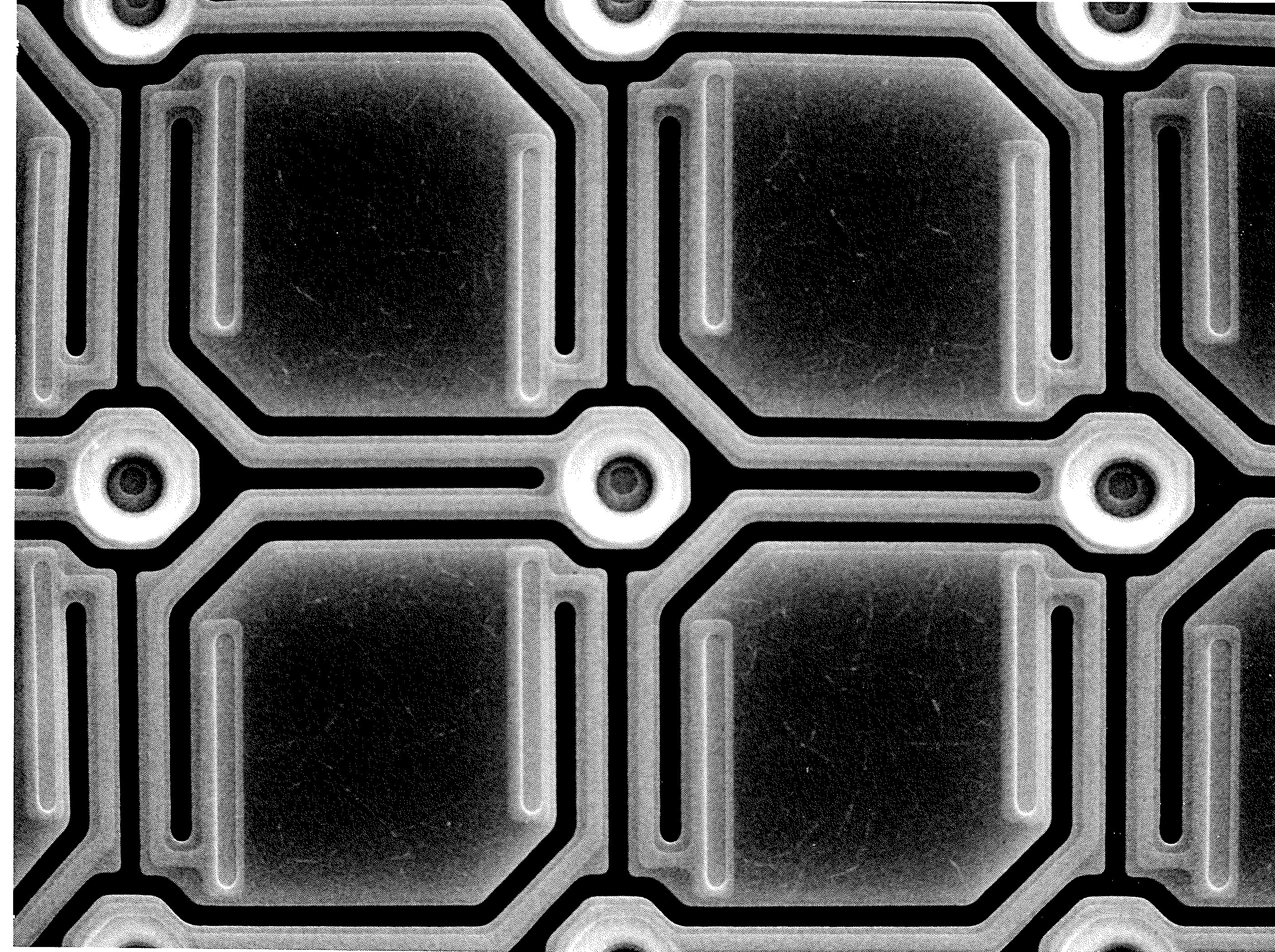

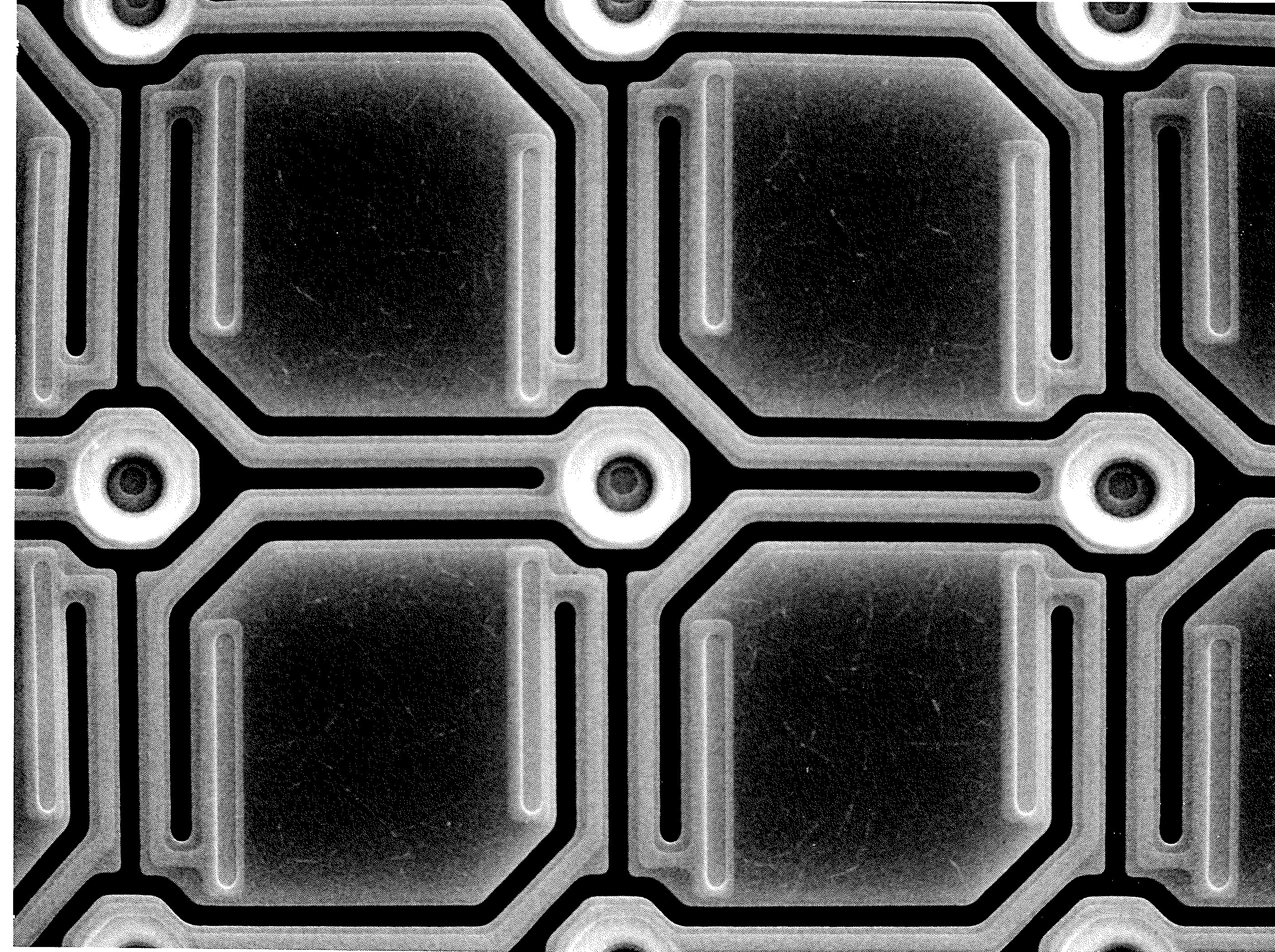

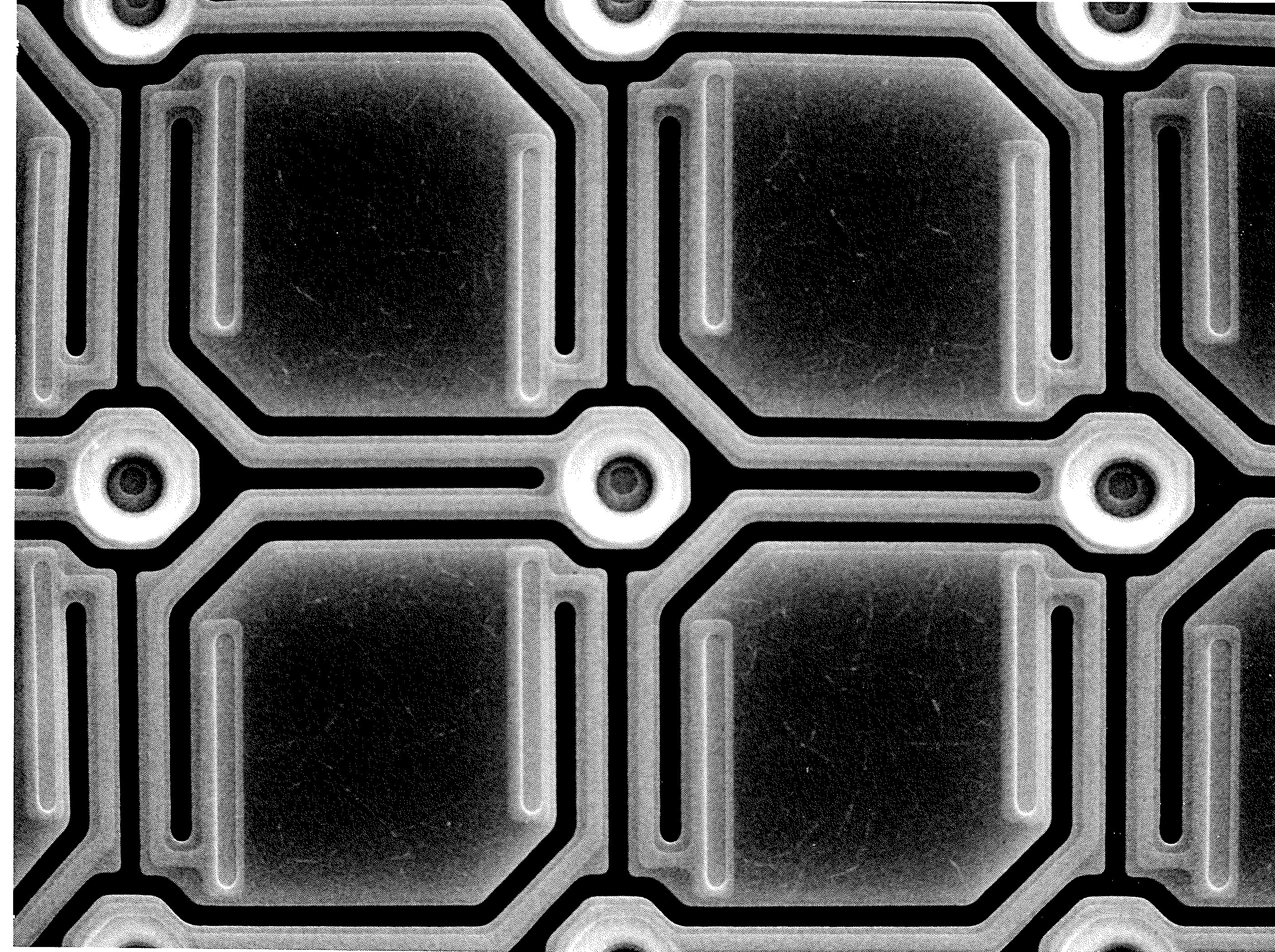

Focused Ion Beam milling uses a gallium ion beam to mill into small (typically tens of microns across or less) sample regions of various materials to expose cross sections of the sample for imaging and critical dimension measurement, either in the FIB itself, using secondary electron and/or secondary ion imaging mode(s), or in the Ultra Field Emission SEM.

Broad Ion Beam milling employs three (3) argon (Ar) ion beams to mill cross sections through structures that are up to approximately 1.5 mm wide and up to approximately 0.5 mm deep, with FIB-quality results.

At temperatures between -196° and -210° Celsius, liquid nitrogen makes many polymer and other soft materials brittle. Cryomillingis a preparation method used to mechanically break apart “bulk” polymer materials into finer grain materials or powders at liquid nitrogen temperatures to facilitate our analysis or subsequent processing by the client.

is a method for mechanically cutting thin or ultrathin sections of materials. This instrument is capable of slicing sections as thin as 40-60 nm for scanning transmission or transmission electron microscopy (STEM, TEM), or as thick as several microns for cross-sectional analysis by FTIR.